Special Lecture & Plenary Talk

Special Lecture

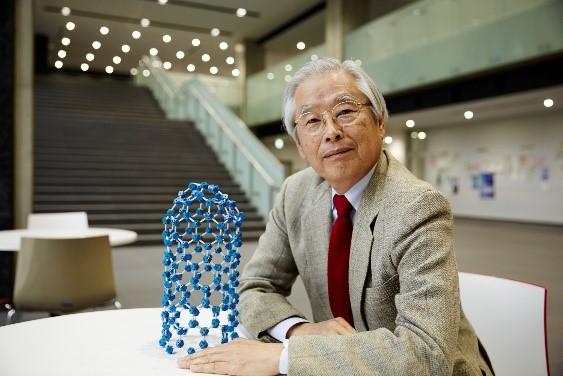

Prof. Sumio IIJIMA

Prof. Sumio IIJIMA(University professor, Graduate School of Science and Technology, Meijo University, Japan)

Atomic resolution EDS-STEM characterization of some energy storage materials

In recent years Ti-Nb-W oxide systems have been investigated as possible candidates for LIBs electrodes. I have studied intensively the oxides in the 1970s using HRTEM and now reinvestigated the same materials using the latest EDS-STEM method which enables us to characterize crystal structures at atomic column to column resolution. The elemental mappings of the cation distributions disclosed the cations ordering in these mixed ternary oxides. The method will be compared with conventional X-ray or neutron diffraction methods.

In recent years Ti-Nb-W oxide systems have been investigated as possible candidates for LIBs electrodes. I have studied intensively the oxides in the 1970s using HRTEM and now reinvestigated the same materials using the latest EDS-STEM method which enables us to characterize crystal structures at atomic column to column resolution. The elemental mappings of the cation distributions disclosed the cations ordering in these mixed ternary oxides. The method will be compared with conventional X-ray or neutron diffraction methods.

Plenary talk

Prof. Karl S. Ryder

Prof. Karl S. Ryder (University of Leicester, UK)

A Bright Future for Alternative Solvents in Metals Finishing

Here I will speak specifically about the opportunities offered by non-aqueous so-called deep eutectic solvents and ionic liquid analogues in the materials finishing industries. I will describe a range of plating and dissolution processes from anti-corrosion coatings to new battery technologies. I will give details of the plating and characterisation techniques using some novel in-situ methods. I will speak about the advantages and disadvantages of these systems in terms of functionality, sustainability and economic cost.

Here I will speak specifically about the opportunities offered by non-aqueous so-called deep eutectic solvents and ionic liquid analogues in the materials finishing industries. I will describe a range of plating and dissolution processes from anti-corrosion coatings to new battery technologies. I will give details of the plating and characterisation techniques using some novel in-situ methods. I will speak about the advantages and disadvantages of these systems in terms of functionality, sustainability and economic cost.

Prof. Thomas Lampke

Prof. Thomas Lampke (Chair of Materials and Surface Engineering, Institute of Materials Science and Engineering, Chemnitz University of Technology, Germany)

Advanced surface engineering – characteristics, microstructures and properties

Surface engineering encompasses a wide range of processes, which although some of them already look back on a long history, are still subject to continuous further development. The major challenges of our time, such as climate change, the associated question of future mobility, and digitalisation within the framework of Industry 4.0, are currently providing new important impetus here. Especially with regard to the responsible use of resources, surface engineering makes a valuable contribution through the targeted separation of the functions of component surface and component volume. This presentation provides a cross-technology overview of various surface coating and treatment processes from vacuum thin-film technology to thermal and electrochemical coating, thermochemical treatment and conversion coating processes. Interrelationships between the respective, process-specific characteristics and the resulting coating properties are pointed out and complemented by comparative considerations as well as current examples from industrial practice and research..

Surface engineering encompasses a wide range of processes, which although some of them already look back on a long history, are still subject to continuous further development. The major challenges of our time, such as climate change, the associated question of future mobility, and digitalisation within the framework of Industry 4.0, are currently providing new important impetus here. Especially with regard to the responsible use of resources, surface engineering makes a valuable contribution through the targeted separation of the functions of component surface and component volume. This presentation provides a cross-technology overview of various surface coating and treatment processes from vacuum thin-film technology to thermal and electrochemical coating, thermochemical treatment and conversion coating processes. Interrelationships between the respective, process-specific characteristics and the resulting coating properties are pointed out and complemented by comparative considerations as well as current examples from industrial practice and research..

Dr. Timothy Gotsick

Dr. Timothy Gotsick (MacdermidEnthone, USA)

The Evolving Role of Surface Finishing in Modern Industrial Production

With ongoing changes in automotive technology and increasing emphasis on sustainable production techniques, the surface finishing industry will face many challenges in coming years. The increasing electrification of transport, the advent of autonomous driving technology, and the wholesale elimination of entire chemical elements from supply chains all loom large. But these challenges are also opportunities for our industry. We as an industry, as well as our customers, must work together to leverage the knowledge gained and investment made over decades to serve new needs. This talk will discuss our challenges as well as innovative approaches to solving them.

With ongoing changes in automotive technology and increasing emphasis on sustainable production techniques, the surface finishing industry will face many challenges in coming years. The increasing electrification of transport, the advent of autonomous driving technology, and the wholesale elimination of entire chemical elements from supply chains all loom large. But these challenges are also opportunities for our industry. We as an industry, as well as our customers, must work together to leverage the knowledge gained and investment made over decades to serve new needs. This talk will discuss our challenges as well as innovative approaches to solving them.

Prof. Osamu Takai

Prof. Osamu Takai (Kanto Gakuin University, Japan)

Progress in Solution Plasma Research

This paper reports on the progress in “solution plasma (SP)” research. The applications of solution plasma processing(SPP) are syntheses of nanoparticles, surface modification, sterilization of bacteria, water treatment. Nanoparticles of metals, alloys, oxides, nitrides and various types of carbons are synthesized by SPP until now. Some metal nanoparticles act as catalysts for metal plating. The size of particles synthesized decreases these twenty years by SPP. Nanoparticles which sizes are less than around 2 nm are called nanoclusters. We can synthesize nanoclusters by the reduction method by SP and sputtering of electrodes in SP. Metal nanoclusters show different properties from nanoparticles, and indicate insulating or semiconducting behaviors. Nanoclusters are very promising nanomaterials and SPP realizes the mass production of nanoclusters in liquid. Meanwhile, SPP can be used to prepare mesoporous silica to calcinate organic materials. Furthermore, SPP is also effective for surface modification. Surface functionalization of carbon nanotubes and nanoballs is carried out by SPP very well. Therefore SPP is a promising method for new material synthesis and surface modification.

This paper reports on the progress in “solution plasma (SP)” research. The applications of solution plasma processing(SPP) are syntheses of nanoparticles, surface modification, sterilization of bacteria, water treatment. Nanoparticles of metals, alloys, oxides, nitrides and various types of carbons are synthesized by SPP until now. Some metal nanoparticles act as catalysts for metal plating. The size of particles synthesized decreases these twenty years by SPP. Nanoparticles which sizes are less than around 2 nm are called nanoclusters. We can synthesize nanoclusters by the reduction method by SP and sputtering of electrodes in SP. Metal nanoclusters show different properties from nanoparticles, and indicate insulating or semiconducting behaviors. Nanoclusters are very promising nanomaterials and SPP realizes the mass production of nanoclusters in liquid. Meanwhile, SPP can be used to prepare mesoporous silica to calcinate organic materials. Furthermore, SPP is also effective for surface modification. Surface functionalization of carbon nanotubes and nanoballs is carried out by SPP very well. Therefore SPP is a promising method for new material synthesis and surface modification.

Prof. Sungmo MOON

Prof. Sungmo MOON (Korean Institute of Surface Engineering, Korea)

Anodic Oxidation Processes for Metal Surface Finishing

In this lecture, anodic oxidation processes for metal surface finishing, including etching, electropolishing, anodizing and plasma electrolytic oxidation, are introduced on the basis of fundamental principles and their practical applications. Principles of anodic dissolution and formation of oxide films under anodic polarization are compared and three different types of anodic oxide films are introduced in detail. Growth mechanisms of various types of anodic oxide films will be discussed based on the migration of ions through the anodic oxide layers and local dissolution or breakdown of the oxide films under applied high electric field.

In this lecture, anodic oxidation processes for metal surface finishing, including etching, electropolishing, anodizing and plasma electrolytic oxidation, are introduced on the basis of fundamental principles and their practical applications. Principles of anodic dissolution and formation of oxide films under anodic polarization are compared and three different types of anodic oxide films are introduced in detail. Growth mechanisms of various types of anodic oxide films will be discussed based on the migration of ions through the anodic oxide layers and local dissolution or breakdown of the oxide films under applied high electric field.

Special Plenary lecture

Mr. Clive Larson

Mr. Clive Larson (Executive Editor, Transactions of the IMF, Institute of Materials Finishing, Birmingham, UK)

Some structural aspects and future challenges for the global surface finishing industry

Data for various structural parameters eg relationship between surface finishing and manufacturing, average finishing company size (people employed), variation in market share of main process types, ratio of sub-contract to in-house (captive) activity, have been derived for a number of industry sectors globally from, mainly, analysis of national statistics offices figures. These are discussed in the context of challenges facing our industry, such as process replacement due to environmental legislation, and the possible need to adopt new smart technology systems eg advanced automation, robotics, AI and others. The former challenge is something even small finishers can cope with, replacement often being with similar technology, but the latter is a very unfamiliar need, requiring capital expenditure and technological input that smaller sub-contract finishers may not have, and may lead to a change in the balance of sub-contract to in-house operations.

Data for various structural parameters eg relationship between surface finishing and manufacturing, average finishing company size (people employed), variation in market share of main process types, ratio of sub-contract to in-house (captive) activity, have been derived for a number of industry sectors globally from, mainly, analysis of national statistics offices figures. These are discussed in the context of challenges facing our industry, such as process replacement due to environmental legislation, and the possible need to adopt new smart technology systems eg advanced automation, robotics, AI and others. The former challenge is something even small finishers can cope with, replacement often being with similar technology, but the latter is a very unfamiliar need, requiring capital expenditure and technological input that smaller sub-contract finishers may not have, and may lead to a change in the balance of sub-contract to in-house operations.

Invited speaker

| Topics | Name | Affiliation | Abstract Title |

| 1. Surface Treatment Technologies | Prof. Dr.-Ing. Kiyoung Lee | Kyungpook National University School of Nano & Materials Science and Engineering Department of Energy Chemical Engineering |

Formation and modification of anodic TiO2 nanostructures for their use in eneregy applications |

| Prof. Jinsub Choi | Inha University | Anodic stainless steel electrodes for energy storage applications | |

| 2. Industrial Application | Prof.Dr.Uwe Landau | Largentec Vertriebs GmbH, Germany | From university to entrepreneurship- a short walk through a scientific and industrial carrier |

| Prof. G.P. Li | The Henry Samueli School of Engineering , University of California, Irvine,USA | Challenges and Opportunities of Advanced Manufacturing for Sustainable Growth and Zero Carbon Environment | |

| 3. Surface Analysis & Characterization | Prof. Giovanni Zangari | University of Virginia, USA |

Absence of Cubic Symmetry in Ni-Fe Nanoparticles |

| Prof. Chi-Chang Hu | National Tsing Hua University, Taiwan | Crystalline Facet Control of Electroplated Copper Foils for Energy Storage Applications | |

| 4. Environment & Production Management | Prof. Jung Woo Lee | School of Materials Science and Engineering, Pusan National University | Agglomeration-Free Fe3O4 Anchored via Nitrogen Mediation of Carbon Nanotubes for High-Performance Arsenic Adsorption |

| Mr. Graham Armstrong | Sales and Technology Mentor, Indestructible Paint Limited, the United Kingdom | Environmental and Legislative Effects on Anti-Corrosion Paint Coatings | |

| 5. Biofouling, Evaluation and Surface Finishing | Prof. Darla Goeres | Center for Biofilm Engineering, Montana State University, Bozeman, MT 59717, USA | Biofilm & Beer: Chemically aged draught beer line tubing preferentially supports biofilm growth |

| Dr. Dana M. Barry | Clarkson University | Biofilm Problems in Households and Food Processing Industries | |

| 6. General | Dr. Abdelkader Zebda | Laboratoire TIMC-IMAG, Grenoble University Alpes, INSERM/CNRS, Grenoble, France | Implantable glucose biofuel cells |

| Prof. Ji-Hun Seo | Korea University, Korea | Flexible piezoelectric elastomer formed by optimal cross-linking of polyrotaxane |